A sophisticated tool for design and optimization of air-cooled heat exchangers

- A highly customizable tool for simulating tube-fin, micro-channel, wire-fin, and flat tube coils, for air-to-refrigerant heat exchangers and tube-in-tube heat exchangers for fluid-to-fluid heat exchangers

- Model validated with 19 experimental data sets (publications available)

Refrigerant Options

- Pure fluids (R134a, CO2 etc.), and pre-defined mixtures (R410A, R404A, R407C etc.)

- Single phase fluids (e.g., water, glycols etc.)

- Plus all refrigerants available in NIST REFPROP 7.0/8.0, including new fluids such as R1234yf

- User-defined refrigerant mixtures (created on-the-fly), and user-defined external fluid properties (via DLL’s or .FLD files)

- Proprietary implementation for popular refrigerant properties leading to order or magnitude improvement in execution time compared to NIST REFPROP 8.0

Air Side Options

- Multiple fins types (plate, louver, slit, wavy, or bare tubes), with dry air and wet air

- Can account for 2-D air maldistribution on coil face area in velocity, temperature and humidity

- Built-in velocity profiles plus the option to create velocity profiles and to load velocity profiles from CFD output

- Load a fan curve to allow the program to solve for the air flow rate

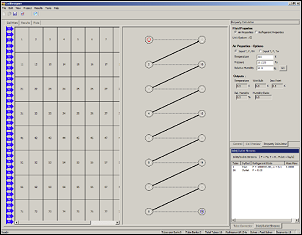

Flexible Tube-circuitry

- Number of tube rows and columns limited by available computer memory only

- Built-in counter-flow circuitry options (tube-fin) and pass-based inputs (microchannels)

- Custom circuitries can be created by connecting tubes on-screen via consecutive mouse clicks

Heat Transfer and Pressure Drop Correlations

- Popular heat-transfer (62), pressure drop (44), and void fraction (15) correlations implemented in the tool for different refrigerant phases, along with user specified correction factors

- Refrigerant specific (e.g., two-phase R410A, supercritical CO2) correlations

Post-processing and Results

- Detailed results available including all properties of interest for all segments and tubes

- Plot for heat load vs. tubes and circuits, outlet air temperature profile and 3-D plots

- 3-D coil drawing with overlaid results

- Export results (and all inputs) to spreadsheet for archiving and further analysis

Sensitivity / Parametric Studies

- Parametric studies can be conducted with one, two or more parameters simultaneously

- Coil dimensions, refrigerant and air side inlet conditions and tube passes can be varied

- Results can be plotted and exported to spreadsheet

Interoperability

- Coils are saved in portable data format and thus can be loaded from any other application

- External communication interface is provided for .NET platform and for Microsoft Excel. Interfaces for other applications or platforms can be developed

Customization Options

- User-defined correlations for heat transfer and pressure drop (refrigerant and air) can be added

- User-defined refrigerants can be added to the program

- User-defined coefficients for standard heat transfer and pressure drop equations can be provided

- Optionally the program allows the user to develop a coefficient file and encrypt it for distribution

- User-defined cost correlations can be added

Optimization Capabilities

- Single and multiobjective genetic algorithms are built-into the program

- The algorithm systematically searches the entire design space defined by the user for optimum coils that meet certain performance (e.g. heat load and pressure drop) requirements

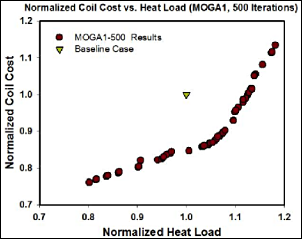

- Results are displayed as a trade-off (Pareto) set between cost and performance

Support Options

- Support available via email, phone and web-based meetings

- ISOC personnel also assist the users in integrating CoilDesigner with their in-house tools

CoilDesigner Multiobjective Optimization with Genetic Algorithms (GA)

CoilDesigner Multiobjective Optimization with Genetic Algorithms (GA)

- Design Options: Tube length, fin density, number of fans, circuits, fan types, motor types, resulting in a total of 125000 possible coils

- The GA evaluated 5000 coils and produced the trade-off set shown on the right

- For the same heat load as the baseline coil, the cost can be reduced by up to 15% or, for the same cost, the heat load can be increased by 12 percent

- GA can be used to systematically search the large design space and find optimum solutions for coil design problems

Top